Aluminum Busbar Manufacturing: Precision Engineering at AP Precision Metals

In the realm of modern electrical systems, aluminum busbar manufacturing plays a pivotal role in ensuring efficient power distribution. At AP Precision Metals, we specialize in crafting high-quality aluminum busbars that meet the stringent demands of various industries, from renewable energy to transportation. Our commitment to precision engineering and advanced manufacturing techniques positions us as a leader in the field.

Why Choose Aluminum for Busbars?

Aluminum offers a unique combination of properties that make it an ideal material for busbars:

- Lightweight: Aluminum’s low density reduces the overall weight of electrical systems, facilitating easier installation and support structures.

- High Conductivity: While not as conductive as copper, aluminum provides sufficient conductivity for many applications, especially when weight and cost are considerations.

- Corrosion Resistance: The natural oxide layer on aluminum surfaces offers protection against corrosion, enhancing longevity.

- Cost-Effective: Aluminum is generally more affordable than copper, making it a cost-effective choice for large-scale projects.

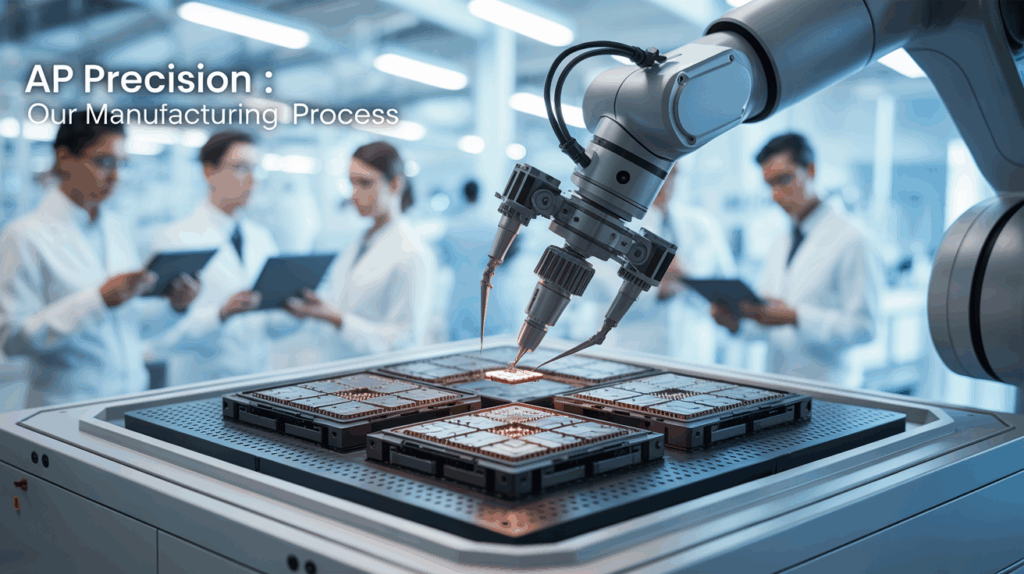

Our Manufacturing Process

At AP Precision Metals, our aluminum busbar manufacturing process is meticulously designed to ensure quality and performance:

1. Material Selection

We begin by selecting premium-grade aluminum alloys, such as 6063-T52, known for their excellent combination of strength, conductivity, and corrosion resistance. This alloy is particularly suited for applications requiring intricate designs and reliable performance.

2. Precision Machining

Utilizing advanced CNC machining and hydraulic press brakes, we shape the aluminum into precise configurations. Our state-of-the-art equipment allows for complex geometries and tight tolerances, ensuring each busbar meets exact specifications.

3. Surface Treatment

Post-machining, we apply appropriate surface treatments to enhance conductivity and protect against environmental factors. Options include tin or silver plating, anodizing, or applying insulating coatings, depending on the application’s requirements.

4. Quality Assurance

Quality is paramount. Each busbar undergoes rigorous testing to verify electrical performance, mechanical strength, and dimensional accuracy. Our comprehensive quality control protocols ensure that every product meets industry standards and client expectations.

Applications Across Industries

Our aluminum busbars are integral components in various sectors:

- Renewable Energy: Facilitating efficient power distribution in solar and wind energy systems.

- Transportation: Used in electric vehicles and rail systems for reliable electrical connections.

- Industrial Equipment: Supporting high-current applications in manufacturing and processing plants.

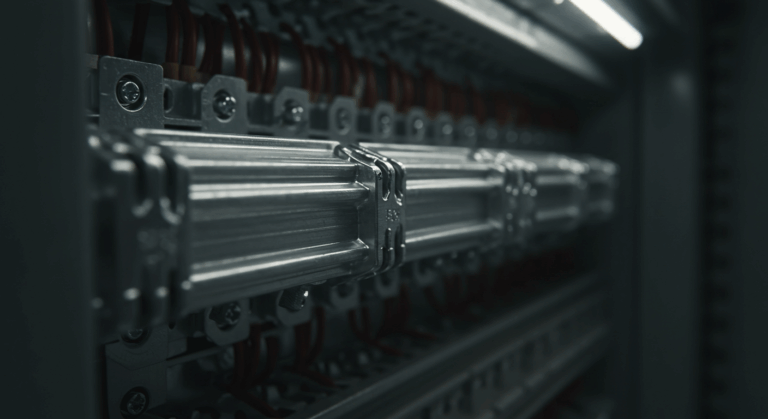

- Data Centers: Ensuring stable power distribution in critical IT infrastructure.

Customization and Collaboration

Understanding that each project has unique requirements, we offer customized solutions tailored to specific needs. Our engineering team collaborates closely with clients to design and manufacture busbars that align with their technical and operational objectives.

Commitment to Sustainability

Aluminum’s recyclability aligns with our commitment to sustainable manufacturing practices. By choosing aluminum busbars, clients contribute to reducing environmental impact without compromising on performance.

Partner with AP Precision Metals

With a focus on innovation, quality, and customer satisfaction, AP Precision Metals stands ready to meet your aluminum busbar manufacturing needs. Our expertise and advanced capabilities ensure that we deliver products that enhance the efficiency and reliability of your electrical systems.

Contact us today to discuss your project requirements and discover how our aluminum busbar solutions can benefit your operations.