The Complete Guide to Aluminum Busbars: Design, Performance, and Applications

As industries continue to demand more efficient, cost-effective, and sustainable electrical systems, aluminum busbars have become a vital component in power distribution across a wide range of applications. At AP Precision Metals, we provide custom aluminum busbar solutions designed to meet rigorous technical requirements while delivering exceptional performance, long-term durability, and reduced costs. This guide explores the full scope of what makes aluminum busbars an essential part of modern electrical systems.

What Are Aluminum Busbars?

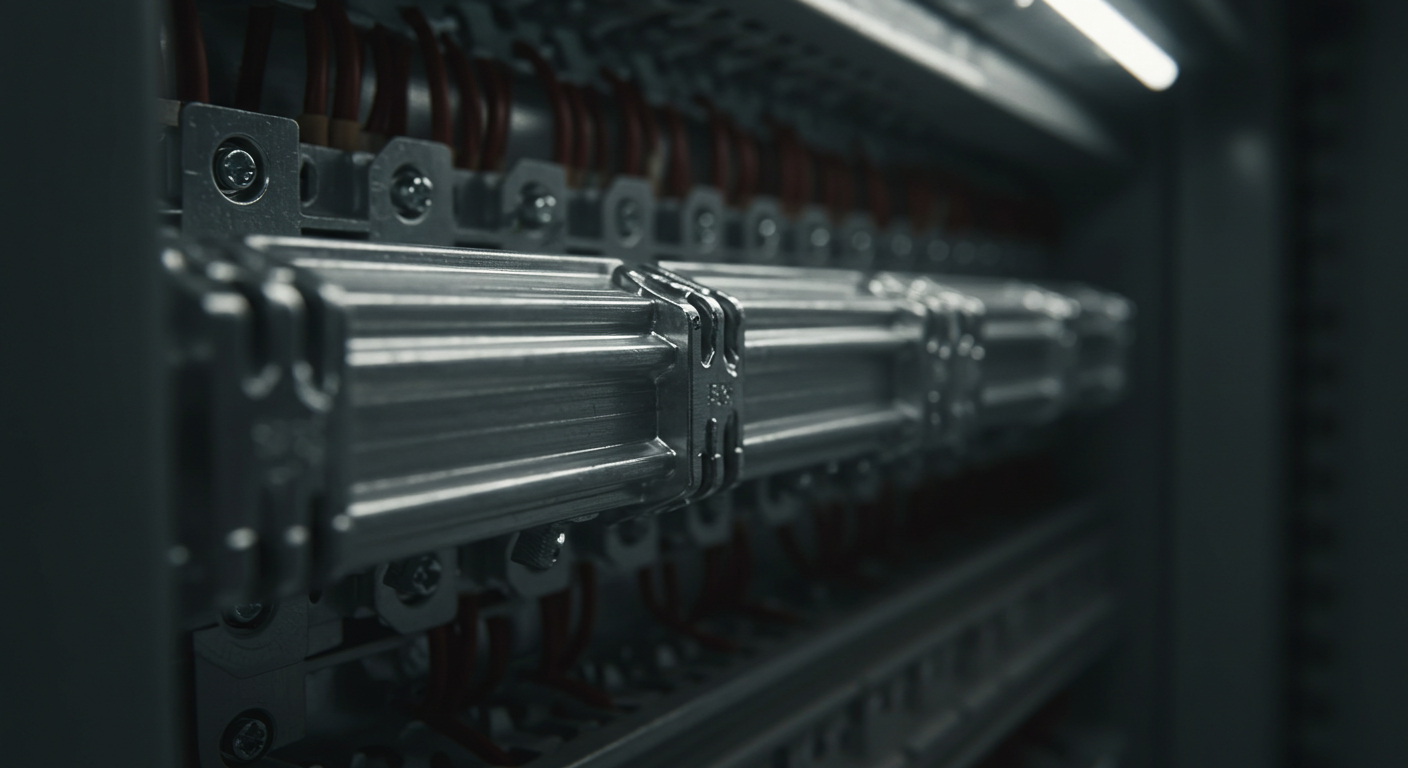

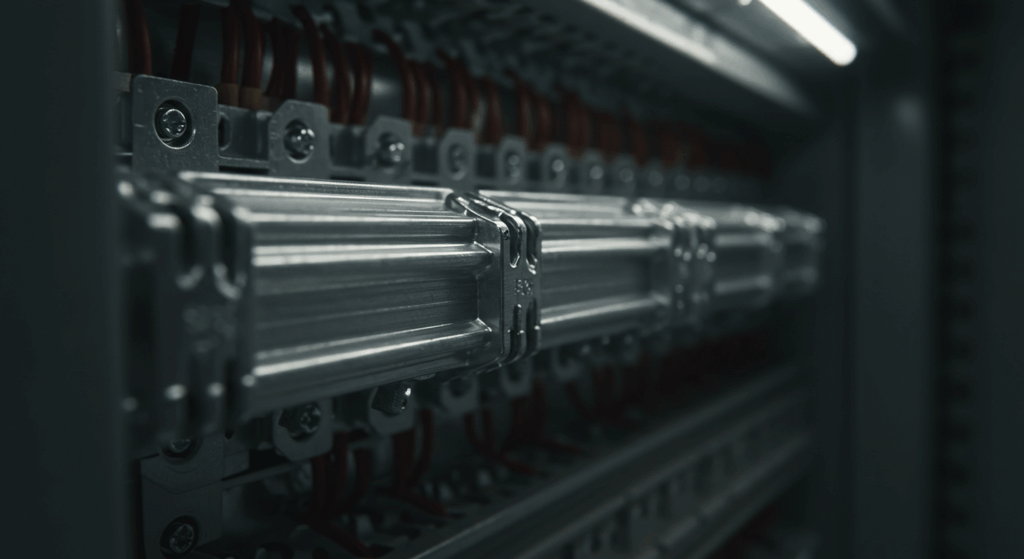

Aluminum busbars are solid, conductive bars made of high-grade aluminum used to distribute electricity within power systems. Typically found in switchgear, distribution boards, battery systems, and control cabinets, busbars offer a compact, organized way to carry high currents with minimal resistance. Their flat or shaped profiles provide increased surface area for better heat dissipation, simplified routing, and easier connectivity.

Compared to traditional cabling, aluminum busbars are cleaner to install, easier to maintain, and offer better performance in high-load environments. At AP Precision Metals, we manufacture aluminum busbars to exacting specifications, ensuring optimal conductivity, mechanical strength, and thermal efficiency.

Why Aluminum? Comparing to Traditional Copper

For decades, copper was the dominant material used for busbars due to its high conductivity. However, aluminum has proven to be a compelling alternative that offers several significant advantages:

- Lower material cost – Aluminum is far more affordable than copper, which is especially important for high-volume or large-scale installations.

- Lighter weight – Aluminum weighs about one-third as much as copper, reducing mechanical load and simplifying installation.

- Good electrical performance – While copper has slightly better conductivity, aluminum’s conductivity-to-weight ratio is actually higher, making it more efficient for many applications.

- Corrosion resistance – When properly treated, aluminum offers strong resistance to corrosion, even in outdoor or marine environments.

- Environmental sustainability – Aluminum is 100% recyclable and requires significantly less energy to recycle than to produce from raw materials.

Materials and Alloys Used in Aluminum Busbars

Not all aluminum is created equal. AP Precision Metals uses high-conductivity, industrial-grade aluminum alloys such as Chalco conductive aluminum, which offer a combination of excellent electrical and mechanical performance. These alloys are designed to reduce resistance, support long-term performance under load, and withstand physical stress in demanding environments.

Design and Engineering Considerations

When designing custom aluminum busbars, precision and planning are key. At AP Precision Metals, we work closely with our clients to ensure each busbar meets all electrical, thermal, and mechanical requirements. Key design considerations include:

- Current-carrying capacity – Determined by the cross-sectional area of the busbar, ambient temperature, and expected electrical load.

- Thermal performance – Heat dissipation is critical to avoid overheating and ensure long service life. Aluminum’s thermal conductivity supports this goal.

- Mechanical stress – Applications exposed to vibration or external forces require thicker or reinforced profiles.

- Spacing and layout – Proper spacing minimizes the risk of short circuits and supports efficient energy flow.

- Connection methods – Precision holes, slots, and bends ensure secure integration with terminals, cables, and connectors.

All these factors are built into our production workflow using advanced CAD modeling and prototyping before full-scale manufacturing begins.

Custom Fabrication Capabilities

At AP Precision Metals, our aluminum busbar production leverages cutting-edge technology to ensure high performance, repeatability, and scalability. Our in-house capabilities include:

Precision CNC Machining

We use advanced CNC machines to cut, drill, and shape aluminum busbars to exact tolerances. This enables complex geometries and consistent quality for large production runs or one-off prototypes.

Laser Cutting and Welding

Laser technology enables us to make ultra-clean cuts and welds that maintain the structural integrity and conductivity of the aluminum. This is especially useful for applications requiring compact, high-current busbar configurations.

Insulation and Plating Options

We offer multiple insulation solutions including epoxy coatings, heat-shrink tubing, and laminated barriers. Plating options such as tin or silver further enhance conductivity and resistance to oxidation.

Cold Spray Coating

Cold spray processes apply conductive coatings at low temperatures, preserving the core properties of the aluminum while improving corrosion resistance and surface conductivity.

Types of Aluminum Busbars We Offer

AP Precision Metals delivers a wide range of aluminum busbar solutions tailored to your application’s needs:

- Flat aluminum busbars – Ideal for traditional power distribution and panel installations

- Extruded aluminum busbars – Provide enhanced strength and customizable profiles

- Laminated aluminum busbars – Reduce inductance and support high-speed switching applications

- Insulated aluminum busbars – Designed for safe operation in compact or enclosed environments

Common Applications for Aluminum Busbars

Aluminum busbars are used in a wide range of industries that require efficient, reliable, and scalable power distribution:

- Renewable Energy Systems – Solar and wind installations use aluminum busbars for connecting inverters, batteries, and distribution equipment.

- Electric Vehicles (EVs) – Busbars reduce wiring complexity and improve battery efficiency.

- Data Centers – Support high-load power distribution in a compact, organized form.

- Telecommunications – Ensure continuous power delivery to mission-critical systems.

- Marine and Aerospace – Lightweight aluminum supports weight reduction and thermal performance goals.

- Industrial Automation – High-current applications in manufacturing facilities benefit from simplified power routing and system reliability.

How Aluminum Busbars Support Energy Efficiency

As energy costs rise and sustainability becomes a priority, aluminum busbars provide a path forward for more energy-efficient infrastructure. Their high thermal conductivity reduces losses due to heat, while their recyclability lowers environmental impact. When paired with intelligent system design, aluminum busbars enable optimized performance with minimal energy waste—making them ideal for green building initiatives and sustainable manufacturing.

Why Choose AP Precision Metals for Aluminum Busbars?

At AP Precision Metals, we go beyond just fabrication—we’re your full-service partner for aluminum busbar design, engineering, and production. Our value lies in a combination of advanced technology, experienced craftsmanship, and a customer-first mindset. Here’s what sets us apart:

- Complete design-to-delivery services – We support every stage of your project, from concept to final product.

- Customization – No two systems are the same, and we tailor every solution to meet your unique needs.

- Advanced manufacturing – Our investment in precision CNC, automation, and quality control ensures consistent performance.

- Responsive lead times – We deliver quickly without compromising quality, helping you meet project timelines.

- Long-term reliability – Our aluminum busbars are built to perform, even in the most demanding conditions.

Start Your Project with AP Precision Metals

If you’re exploring aluminum busbars for your next power distribution project, AP Precision Metals is here to help. Our team of engineers and fabricators will work closely with you to deliver a high-performance, custom-engineered solution that fits your specifications and exceeds expectations.

Contact us today to discuss your aluminum busbar requirements and discover how our precision solutions can power your systems more efficiently.